The stainless steel mesh belt has now become a leader in the transportation industry and is loved by a wide range of users. As a Stainless Steel Wire Mesh Manufacturer, share with you. The filter must be sprayed during the application process. As long as this is the best way to protect it, then about the spraying of the stainless steel filter What are the first and foremost solutions?

The pretreatment of the stainless steel mesh belt, in order to make the coating film strong, not easy to fall off, and long life, the appearance of the stainless steel mesh belt must be pretreated before spraying. Coating dryness is divided into physical dryness and chemical dryness according to the nature of the coating itself. The pretreatment of the Great Wall mesh belt is very tied, and spraying also requires a process. It is divided into three processes. First, pretreatment is performed by the predecessors, then spraying, and finally boring. The order of the three processes cannot be interchanged. There are dozens of paints such as grease paint, natural resin, epoxy resin, phenolic resin, etc., which can be selected according to actual conditions.

The spraying process and methods are also different according to the type, function and curing conditions of the coating. Users can choose according to the shape, size and batch size of the stainless steel mesh belt. In practice, for rapid drying, solvent volatile coatings or thermal curing coatings are often used, and the ideal effect can be achieved through natural drying or simple drying processes. Steel parts are mainly degreasing, derusting, phosphating and other treatments. Commonly used water-based cleaning liquid decontamination and degreasing, mechanical or chemical derusting, phosphating is to immerse the parts in an acid diluent (density 1~1.1, PH =1~3), there will be a response at the interface of the two.

The Stainless Steel Filter Screen is boring. In order to make the coating function excellent, strong and wear-resistant, it must be used after it is fully boring. Different stainless steel mesh belts have different pretreatment methods. There are many methods for spraying, such as manual, active, electrostatic, electrophoresis, etc., which can be selected according to the batch size and appearance of the Great Wall mesh belt.

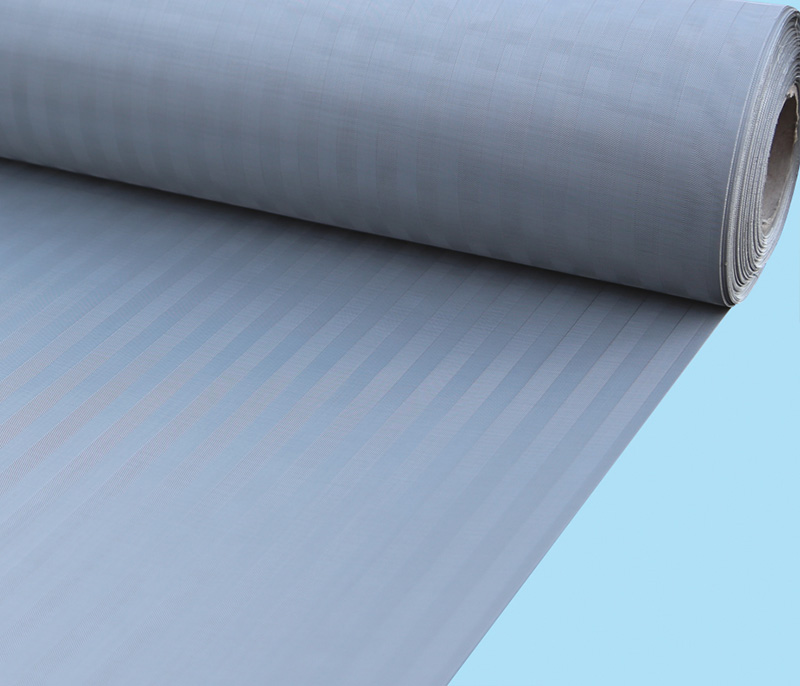

Our stainless steel mesh has advantages and features, but many people still don't know what our stainless steel mesh is used for.

In fact, many times are used to filter some acid and alkali components with stainless steel screens. In many times, we choose stainless steel mesh, nickel wire, and copper wire as materials. Yes, but after many hours of use, I still feel that this stainless steel mesh is the best.

Because it has plain weave, twill weave, mat weave, herringbone weave, and the function of our product is also very stable, and our stainless steel mesh can also be easily cleaned. The behavior of straight seam steel pipe is still not rusty.

Previous: Gabion Basket Gabion Retaining Wall Galvanized Gabion Box pvc coated gabion box Suppliers

Next: Grassland Fence

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used