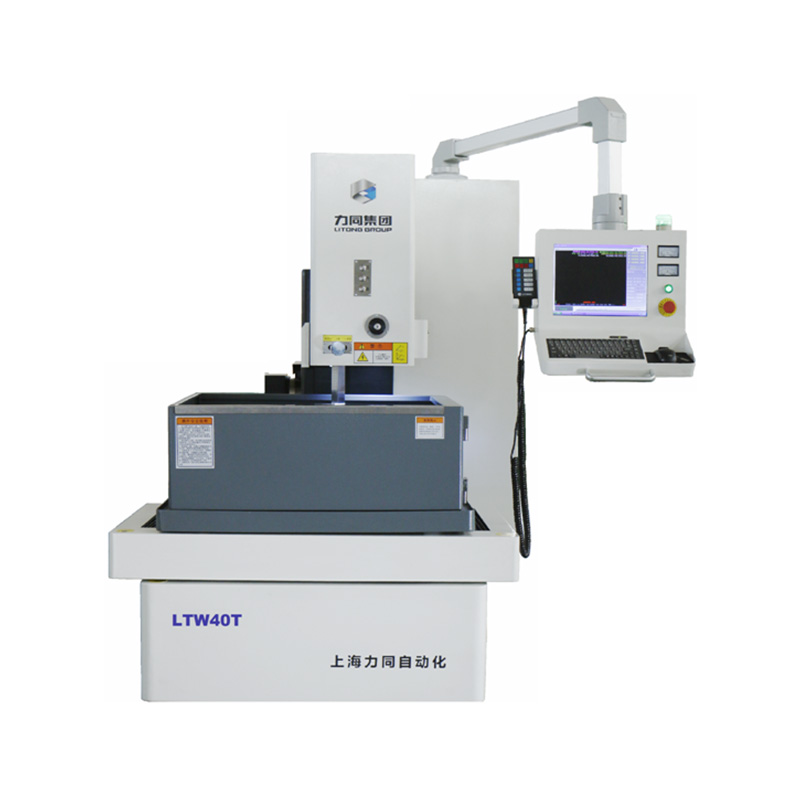

Spark machine, referred to as EDM, is a kind of mechanical processing equipment, mainly used for electric spark processing. Widely used in all kinds of metal mold, machinery and equipment manufacturing. It is a special processing method of removing conductive materials by means of electroerosion generated by pulse discharge between two poles immersed in working liquid, also known as discharge machining or electroerosion machining.

Edm wire cutting machine, referred to as WEDM, belongs to the category of electrical processing, is the former Soviet Union by lazalenko couple research spark discharge corrosion damage phenomenon and reasons, found that the instantaneous high temperature of electric spark can make the local metal melting, oxidation and corrosion, so as to create and invent the edM processing method.

According to the data, many people in the machine tool industry have confused the concept of spark machine and wire cutting. Spark machine is also known as electric spark, but wire cutting is also called electric spark wire cutting, so in the name of a lot of people confuse these two, collectively referred to them as electric spark. Although the name is the same, but the two are clearly different. Here's a look:

The same thing: Both work the same way, dissolving metal by generating high temperatures in an electric discharge. Surface roughness and machine productivity and other processing technology similar, can process all conductive materials. There is a limit to the minimum angular radius of both.

Different place: electric spark is in the processing of the workpiece on the spark pattern and wire cutting is on the workpiece spark discharge, cutting molding. Edm must first process the shape of the electrode through other CNC machine tools to create, wire cutting is through the movement of the table, molybdenum wire on the workpiece profile processing. Spark machine is very easy to wear, so often use multiple electrodes processing; The wire cutting will automatically replace the damaged electrode wire in the process of machining, so there is no problem that the electrode damage affects the machining accuracy. Sparks can produce beautiful patterns; Wire cutting can process holes and complex shapes of joints.

Previous: Dry skin like fish scales ichthyosis, really only appearance PROBLEM?

Next: Car Window LED Display

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used