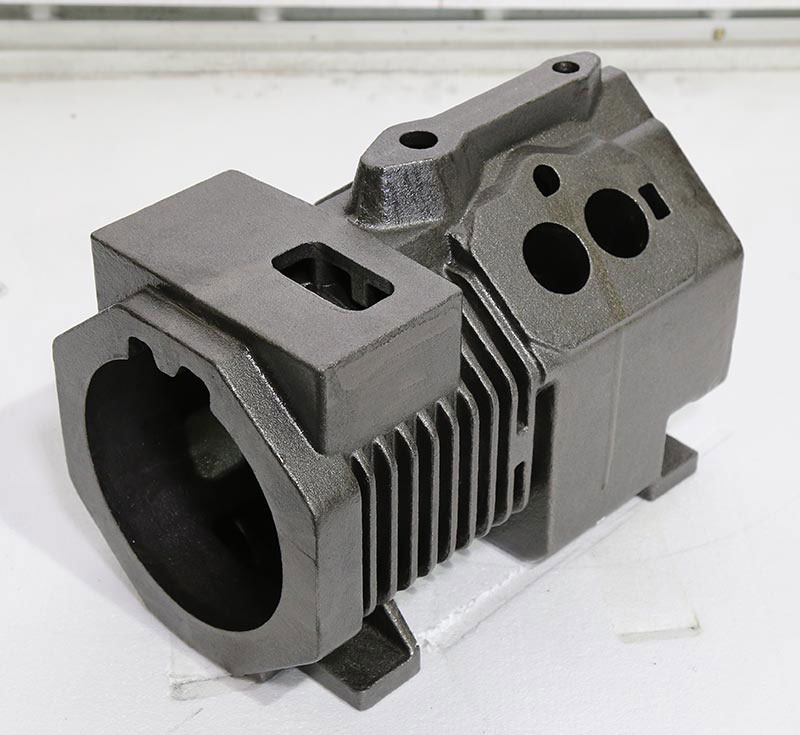

Know the Parts of Your Air Compressor Castings

Actuators: The actuator produces rotary or straight activity and also is what outputs the compressed air to the devices or procedures that make use of pressurized air for power. Any kind of leakages or other deficiencies in the air motion entering into the actuator will lead to a decline of the flying force appearing. Small fragments that have actually found their method into the air will create obstructions in the actuator, in addition to several other parts of your air compressor.

Bearings: Industrial-class bearings guarantee a long operating life for the most requiring of procedures. Quality bearings will certainly offer you comfort as your air compressor operates at high transformations with high pressure. Bearings are very based on the appropriate lubrication at the ideal thickness.

Belts: Belt tension should be checked every 40 hrs for wear and also operation. Working to drive the procedure of your compressor, the belts need to be of the finest and fit effectively.

Bumpers: Valve bumpers surround the shutoffs for added protection from accidental get in touch with. Replace this small securing part when required to prevent the much more pricey replacement of shutoffs.

Bushings: Bushings create some room in between moving parts. Utilized in the inner parts of the air compressor, your bushings supply protection from major break downs, reducing side-to-side play.

Attaching Rods: Used to move the piston up and down in the crankcase, the linking rods take a heavy work. They are a highly durable part of your air compressor. You may never require to change connecting rods, unless appropriate maintenance is not carried out frequently on your system.

Couplings: Used on interior elements to avoid dripping from the high-pressure system.

Desiccant Dryers/Q-Sorb: Our air clothes dryers cleanse your compressed air by absorbing water vapor. A flow of 'damp' compressed air is travelled through two pressurized containers which contain our very absorptive desiccant. Q-Sorb is a sophisticated formula of turned on alumina that substantially decreases operating costs. Maintain your air dryer running efficiently with regular checks of desiccant and also filters.

Gaskets & Seals: For trustworthy air circulation and to keep intended pressure, your air compressor ought to be air tight with top quality seals as well as gaskets. There are various sections of your air compressor that have gaskets and also seals: valve plate to head gasket, crankcase gasket, intercooler gasket, oil seal, as well as the shaft seal, among others. These tiny components keep contaminates out and the pressurized air within.

Scales: The gauge on your air compressor gauges the stress of the air in your container. Your scale is informative in a number of means, especially for everyday checks to ensure your pressure is at the designated degree, so you can attend to any kind of shortages asap.

Motors: In general, your air compressor has an electrical motor to run the operation of pressing air. Different compressors require various dimensions of motors (hp). If you're replacing a worn-out electric motor, make certain to have actually the suggested replacement motor installed.

O-Rings: Used for a limited seal, O-rings aid maintain your system performing at peak performance.

Piston Rings and Rods: Our reciprocating piston designs develop atmospheric pressure with the movement of the piston and attaching poles. These parts are under great pressure when in motion and call for a lubricating substance without contaminates and of the highest quality. Fluid evaluation of your QuinSyn fluid in a rotating screw compressor is necessary for the overall feature of your air compressor as well as to identify feasible problems early. It's likewise specifically important to use Quincy oil to avoid early using of your piston rings that prevent extreme oil carryover.

Rotors: In our rotary screw air compressors, setting up contains 2 interlacing helical rotors that compress the air coming in via the inlet shutoff. With appropriate operation, these rotors have an exceptionally lengthy life.

Shims: Adding sustaining spacers in the installment of your air compressor may be required. These steel shims will give you with the needed assistance for a dependable system.

Springs: Various components of your compressor usage springs for the mechanics of the system. Figure out when to replace springs with routine solution checks.

Valves: Allowing air in and out, draining water, and also controling air circulation, valves are a crucial part that need normal assessment throughout your period checks as well as regular maintenance. Our top quality engineered valves are developed for resilience and also a long life. They operate with the highest efficiency, making use of Buna-N or Viton seats as well as seals.

Familiarize Yourself With Regular Replacement Parts

Air/Oil Separator: Regular checks of these elements and the regular replacement of filters should be part of your maintenance schedule before they become clogged, resulting in a loss of performance.

Inlet Air Filter: As another preventative measure to keep foreign particulate matter from entering the air compressor system, the inlet air filter should be replaced at regularly scheduled intervals or if an inspection indicates the need to replace the element.

Oil Filter: Maintain the necessary quality of your lubricant with appropriately scheduled fluid changes and oil filter replacements that are geared to the activity of your system and working environment. Our fluid sampling program for rotary screw compressors will provide you with the necessary information to define the appropriate schedule for your air compressor.

Previous: Framed Vs Frameless Shower Doors

Next: Glass Clip YD-RGC02

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used