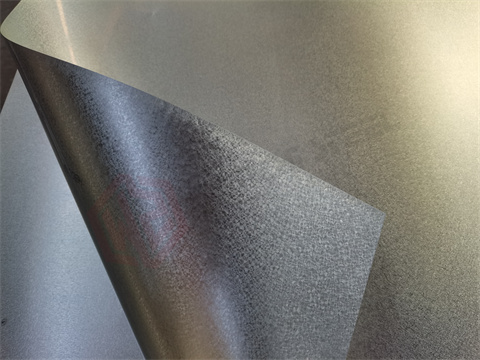

GI sheet stands for galvanized iron sheet, which is a sheet of steel that has been coated with zinc to prevent corrosion. In the process of galvanizing, the zinc coating is done on the iron or steel to make it rust free. Besides protecting the steel from rust and corrosion, the zinc also keeps the initial strength of the steel intact for long time and gives polished finish to the sheet. Generally, people are familiar with two kinds of GI sheet: hot dipped and electro-galvanized steel sheets.

GI Sheet Properties

1. Environment-friendly and chromate-free. With the emergence of commercialization of the world first chromate-free galvanized steel sheet in 1998, today all galvanized steel sheets are chromate-free. It not only makes for environmental protection, but also complies with various regulations, such as RoHS and ELV, which can be used extensively without problems.

2. Excellent corrosion resistance. The steel sheet is covered with a uniform zinc-plated layer by controlling the amount of zinc coating. The zinc-plated layer itself is chemically treated to ensure excellent corrosion resistance.

3. Outstanding appearance and workability. The galvanized surface is smooth and uniform, thanks to advanced production facilities and a sophisticated quality control system that guarantee excellent workability, paintability, and weldability.

4. Wide product range. It can be applied to automobiles, electrical appliances, and construction materials, etc.. The quality of the base steel, the amount and composition of the zinc coating, and the subsequent chemical conversion coatings all can be specifically designed to provide optimum performance for each application.

1. Welding process to form one continuous sheet by welding the steel sheet ends which has been sheared to the preceding sheets;

2. A straightening process where a high-performance tension leveler is normally employed to straighten the steel sheet for getting good flatness;

3. Cleaning process in which initially the steel sheet is cleaned in an alkali bath and brushed for initial degreasing so as to reduce surface oxides for achieving complete adhesion of the coating and then the sheet is dipped in an acidic bath to activate;

4. Continuous annealing process which involves the reduction of the oxidized film on the surface of the steel sheet by passing it continuously through a reduction furnace;

5. Galvanizing process in which, the sheet is left in a reduction atmosphere and immersed directly into a bath of molten zinc and the steel sheet is then rolled around a roller which is dipped into the coating bath and is removed from the bath vertically by pulling;

6. Removal of excess molten zinc, using high-pressure air which is carried out to achieve a coating thickness that can be closely controlled;

7. Chemical treatment process in which the coated zinc sheet is exposed to different chemical treatments according to the desired use. The treatment includes phosphate treatment for excellent paintability, and chromate-free special treatment for good corrosion resistance.

Types of GI Sheet

According to production and processing methods, they are:

1. Hot dipped galvanized steel sheet. The thin steel plate is immersed in the molten zinc tank so that a thin steel plate with a layer of zinc adheres to the surface. At present, the continuous galvanizing process is mainly used for production, that is to say, the rolled steel sheet is continuously immersed in the galvanized bath with the molten zinc to make the GI sheet;

2. Electro-galvanized steel sheet. The galvanized steel sheet produced by the electroplating method has good workability. However, its thin zinc layer leads to a result that the corrosion resistance is not as good as that of a hot-dipped galvanized steel sheet.

GI sheet refers to a steel sheet coated with zinc on the surface. Galvanizing is an economical and effective anti-rust method that is often used. About half of the world’s zinc production is used in this process. So combined with the above characteristics of GI sheet, it will have a promising market and great processability. Wanzhi Steel, as the professional galvanized coil manufacturer and supplier from China, has maintained a constant belief: first-class quality, professional services, and technology leadership. Looking forward to cooperating with you!

Previous: Canopy Room

Next: Steel Truss Stadiums

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used