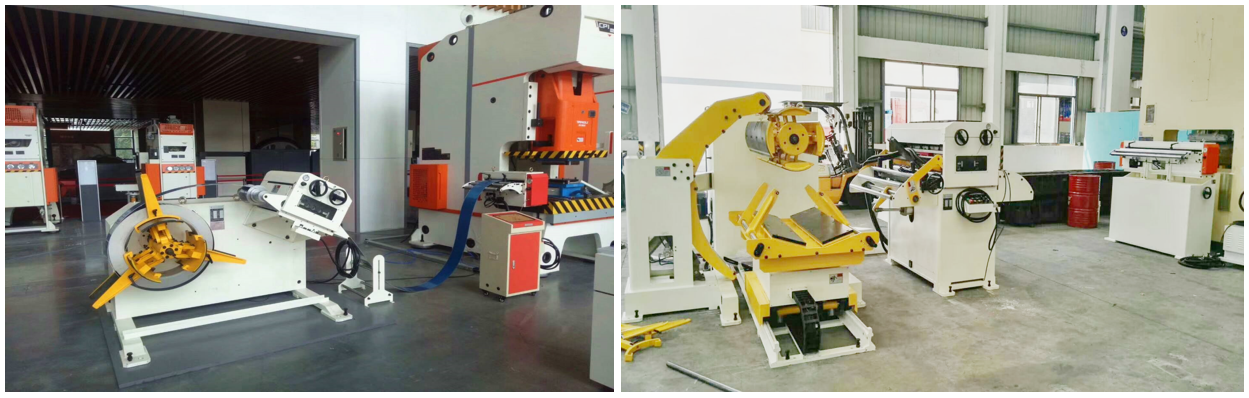

Two common configuration methods of traditional split type automatic coil feeding line are as the below:

1. Decoiler machine/ Rack--- Straightener machine/ Leveling machine --- Coil Feeder machine

2. Combo decoiler straightener 2 in 1 machine ---- Coil Feeder machine

Although the two types of coil feeding line can meet the requirements of feeding, there is still also some insufficient place, so we recommend the compact decoiler straightener feeder machine which can solve the shortage of the traditional split type coil feeding line, then what are the differences ?

Here with 3 differences between traditional split type decoiler, straightener, feeder machine and compact coil feed line.

1. The difference in Installation and debugging

The traditional stamping automatic feeder production line begins with coil decoiler machine and leads the coil strips through the leveling machine into coil feeder and then feed the coils strips into stamping press or it begins with combo decoiler straightener and lead the strips into coil feeder machine and feed the strips into stamping press. The decoiling, levelling and feeding commissioning process is very complicated, waste a lot of manpower and material resources, and what’s more, if the heavy coils are used, when cutting the coil tie belt, it is necessary to use the pressing arm to press and then cut it, and the feeding needs more people to assist the traction and feeding, and before using the operation, the material rack, leveling machine and coil feeder also need to be separated to operate and debug, and the operation is complicated.

A compact coil feed line combined the decoiler, straightener and feeder part into 1 unit, so after uncoiling the coils, the Keep-offing arm will automatically lead the coil strips into the straightener and feeder part and the swing arm press the coils strips into leveling rollers to feed it into stamping presses. It’s very easy and simple operation and save lots of manpower and time.

2. The difference in structure

The speed of split type decoiler, straightener, feeder machine is inconsistent, a loop is between each machine which is used to prepare to storage the material and avoid lack of coil materials, the length of loop depends on the thickness, width and feeding pitch of coil materials, so the production layout, need to occupy a lot of work space. The compact coil feed line will be the decoiler, straightener, feeder integration, greatly reduce the production layout of the customer workshop and the occupied space is also reduced to the minimum.

3. The difference in operation

The split type decoiler, straightener, feeder machine is independent and separate, it is difficult to ensure the accuracy of the product rushed out of the operation, but the compact coil feed line has high synchronization, and the leveling and feeding process are carried out synchronously, which ensures the accuracy.

Also a compact decoiler straightener feeder machine in not only a simple combination of decoiler, straightener and feeder but also highly integrated control in operations. A hydraulic station, uncoiling motor, inverter and straightener feeder servo motor are all connect with the PLC modular systems and controlled by touch screen, which is quite convenient for operators.

The above three points are the main differences between the split type decoiler, straightener, feeder machine and compact coil feed line. Both of them also have different advantages and disadvantages. Therefore, the specific choice of automatic production line mode also needs to see the accuracy requirements of the customer's products.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used