Ram BOP Holes Safety and reliability are paramount in the oil and gas industry. Various equipment and systems are employed to ensure the smooth and safe operation of drilling rigs. A key component that plays an important role in well control and blowout prevention is the ram blowout preventer (BOP). Among its many functions, the ram BOP hole stands out as a key aspect that requires attention and understanding. In this article, we take a deep dive into the importance of ram BOP holes and their impact on drilling operations.

What is the ram BOP aperture?

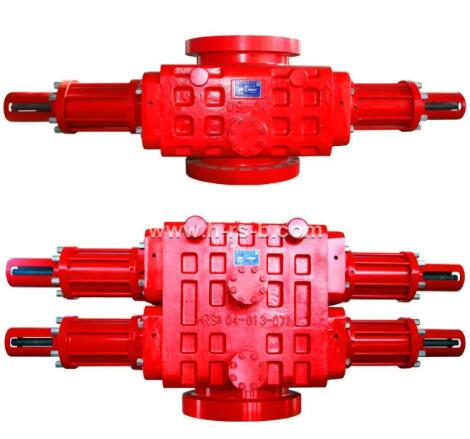

Ram blowout preventers are an integral part of well control systems designed to quickly seal the wellbore and prevent the uncontrolled release of hydrocarbons. It consists of one or more sets of hydraulic cylinders, which are large, heavy steel plates that can be enclosed around drill pipe, casing, or other tubular components in an emergency. The ram BOP hole refers to the central opening or cavity in the BOP where the ram is installed.

The importance of ram BOP holes:

Well control blowout prevention:

The primary function of the ram BOP hole is to provide a reliable seal around the tubular member, effectively shutting off fluid flow in the wellbore during well control operations. By closing the ram around the pipe, the ram BOP holes form a tight barrier, preventing hydrocarbons from escaping and minimizing the risk of a blowout. This important function helps protect the rig, personnel and the surrounding environment.

Compatibility and flexibility:

Ram BOPs are available in a variety of sizes and configurations to suit different well conditions and drilling operations. The size of the ram BOP holes is carefully selected to match the diameter of the tubular components used. Ensuring the correct bore size is critical for proper installation and effective sealing, allowing compatibility and flexibility when dealing with different well bore sizes and pipe sizes.

Reliability and Performance:

Ram BOP holes must be carefully maintained to ensure their optimum performance. Regular inspection, maintenance and testing are essential to verify bore integrity and plunger functionality. Any signs of wear, damage or deformation in the bore or plunger must be addressed promptly to maintain the reliability of the BOP. Proper lubrication and adherence to manufacturer guidelines are critical for smooth operation and long life.

Emergencies and contingency plans:

Ram BOP holes play a critical role in quickly isolating the wellbore and restoring control in the event of an emergency such as a kick or blowout. Rig operators and personnel must be well trained in the operation and activation of ram BOPs to ensure rapid response and minimize potential risks. Regular training drills and contingency plans involving ram BOP holes are essential to enhance preparedness and mitigate the effects of critical situations.

in conclusion:

The ram blowout preventer hole is the basic element to ensure well control and blowout prevention in oil and gas drilling operations. Its correct size, reliable performance and effective sealing capabilities are critical to maintaining a safe and secure drilling environment. Rig operators, drillers and maintenance personnel must be well versed in the importance of the ram BOP holes and adhere to strict maintenance practices and emergency protocols. By prioritizing the integrity and functionality of ram BOP holes, the industry can improve operational safety, minimize risk, and protect people and the environment from potential hazards.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used