Material Composition:

High-tensile galvanized steel core wire (2.5 mm diameter).

Galvanized steel blade/strip (0.5 mm thickness) formed into razor-sharp barbs.

Barb Spacing and Length:

Barbs spaced at approximately 26 mm intervals.

Each barb measures roughly 15 mm long and 13 mm wide.

Coil Construction:

Razor wire coils arranged in a Coil Pyramid configuration with three concertina layers.

Each coil measures approximately 730 mm in diameter when fully deployed.

Coils preloaded in modules with a minimum length of 75 meters per module.

Equipped with anti-tangle strut wires to maintain coil separation.

Support Structure:

Top support wire: 4.0 mm galvanized steel.

Straining wire: 3.5 mm galvanized steel, tensioned to maintain coil alignment.

Ancillary Equipment:

Heavy-duty dove-tail clips for securing overlapping coils.

Clip applicators for fast and secure attachment.

Ground locking pegs for stabilizing the base of the coil pyramid.

The Razor Wire Barbed Tape is designed to prevent intrusion along perimeter barriers. It should be fabricated from high-tensile wire, which is virtually impossible to cut with standard tools, and feature a multitude of razor-sharp barbs formed at close intervals. The barbs must be designed to provide both piercing and gripping actions. The wire and strip should be constructed from galvanized steel to ensure corrosion resistance.

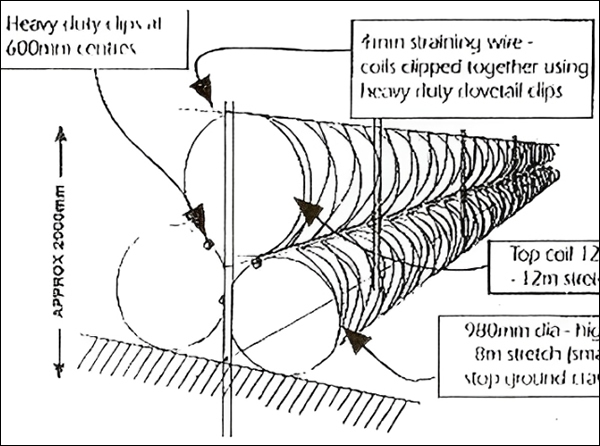

The fencing should be constructed in a Coil Pyramid with Top Support Wire, as depicted in the following diagram.

The fence system is designed for high-security applications, featuring a robust structure and compact configuration to prevent intrusion and ground crowding.

Heavy-duty clips spaced at 600 mm centers: Clips are installed every 600 mm to secure the coils.

4 mm straining wire: The coils are fastened together using heavy-duty dovetail clips.

Top coil with a diameter of 1250 mm: This is a standard coil with a stretch length of 12 meters.

High-density coil with a diameter of 980 mm: This coil has a stretch length of 8 meters and features a smaller aperture to prevent ground crowding.

Packaging:

The Razor Wire Barbed Tape must be factory-packaged in a manner that allows rapid deployment from a motorized trailer.

All three coils must be deployed simultaneously from the trailer, requiring only ground support and the installation of clips to secure individual coils together.

Preloading and Configuration:

The coils must be preloaded in magazines to enable rapid deployment.

High-tensile anti-tangle strut wires must separate the coils.

Each coil must be supplied in minimum lengths of 75 meters and compressed into compact modules.

Material Specifications

The Razor Wire Barbed Tape must be constructed from the following materials:

Wire: 2.5 mm high-tensile galvanized steel.

Blade/Strip: 0.5 mm galvanized steel.

Configuration

The Razor Wire Barbed Tape should be configured as shown in the diagram below.

This product ensures high security, durability, and ease of deployment, making it ideal for perimeter protection.

Previous: Welded Wire Mesh Panels

Next: Mesh color-coated steel: innovative materials, beautifying living space

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used