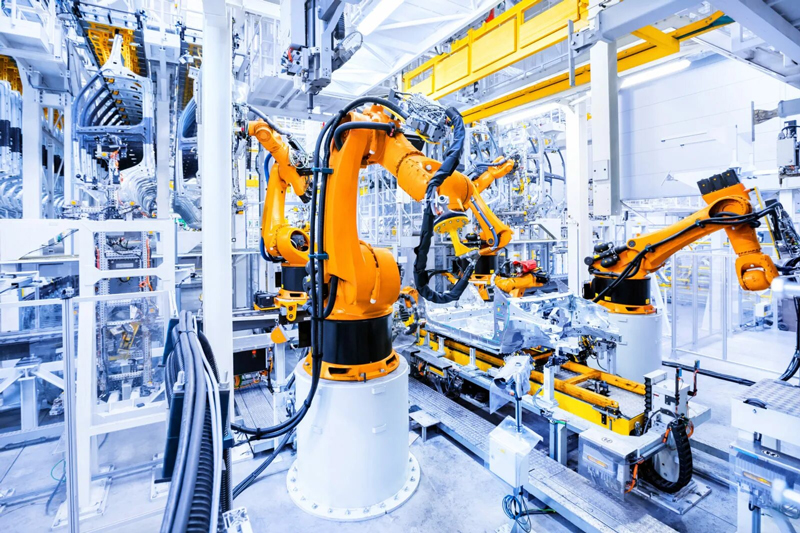

With the rapid development of intelligent manufacturing technologies, the die casting mold industry is undergoing a technological revolution. In recent years, automated production lines and digital process management have been widely applied, especially in mold design, processing, inspection, and assembly.

Industry experts point out that the integration of artificial intelligence (AI) and the Internet of Things (IoT) has become a key factor in improving mold production efficiency and quality. For instance, with AI-assisted design systems, companies can optimize complex molds in a short period, significantly reducing product development cycles. At the same time, intelligent inspection equipment can monitor the production status of molds in real-time, ensuring that product quality meets high standards.

Industry Outlook:

As more companies introduce intelligent technologies into their production processes, die casting mold production will become more efficient, precise, and flexible. This transformation not only helps to increase productivity but also enables customized production and rapid market response.

In the future, the mold industry will face increasingly intense market competition. Only through technological innovation and intelligent upgrades can companies stand out in the global market.

Previous: Top 7 Benefits of Using a Surface Core Drilling Rig for Efficient Exploration

Next: IEC Standard/ GOST Standard Medium Voltage Electric Motors/Asynchronous Motors

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used