Wire rope slings are essential for lifting heavy loads safely and efficiently. They offer strength, durability, and flexibility for various industrial applications. As a leading Chinese supplier, we provide high-quality wire rope slings that meet global standards.

In this article, we explore the different types of wire rope slings and their eye configurations. We also highlight why our products stand out in the market.

Wire rope slings consist of steel wires twisted into strands for maximum strength. They are widely used in construction, shipping, and oil & gas industries. Their durability and load-bearing capacity make them a top choice for heavy lifting.

The performance of a wire rope sling depends on its construction and wire rope sling eye types. Proper selection ensures safety and efficiency in demanding environments.

Wire rope slings come in several configurations, each suited for specific applications. Below are the most widely used types:

Made from a single length of wire rope.

Flexible and easy to handle.

Ideal for general-purpose lifting.

Consist of two or more wire ropes.

Provide higher load capacity.

Used in heavy-duty industrial lifting.

Constructed by braiding multiple wire ropes.

Offer superior flexibility and abrasion resistance.

Perfect for complex rigging setups.

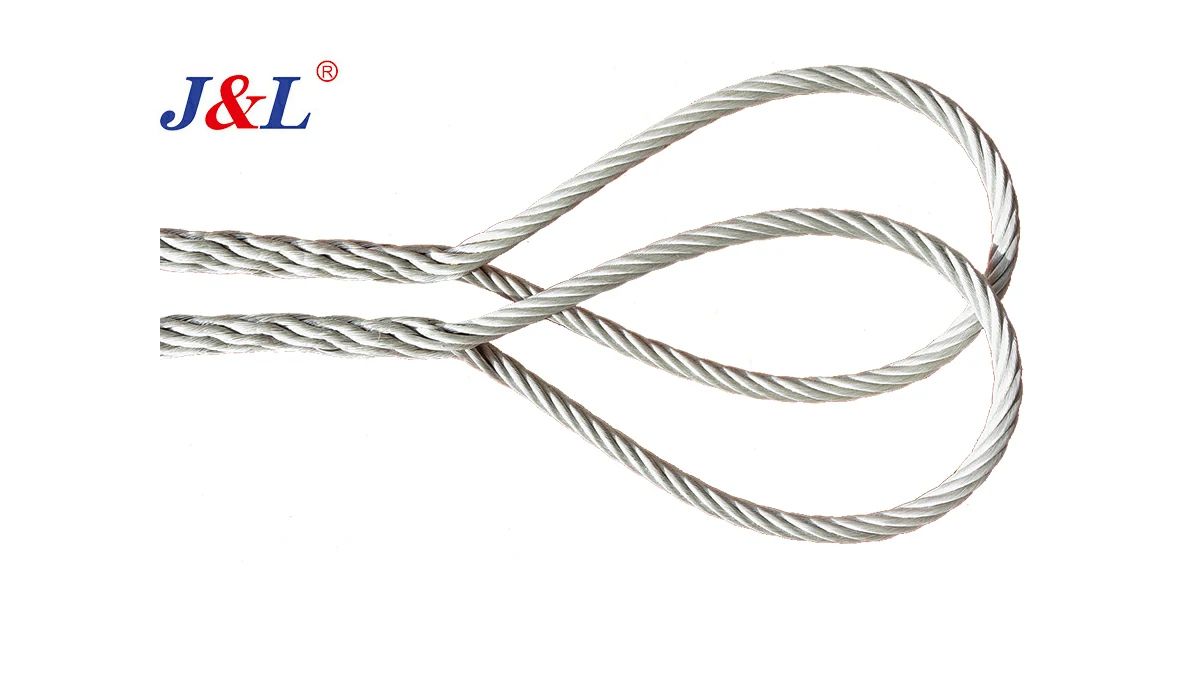

Formed by splicing wire rope into a continuous loop.

Distribute load evenly.

Suitable for repetitive lifting tasks.

The wire rope sling eye types define how the sling attaches to lifting equipment. Choosing the right eye type ensures secure and efficient load handling.

A loop created by splicing the rope back into itself.

Provides a smooth, durable connection.

Reduces wear on the sling.

Uses metal sleeves or fittings to form an eye.

Quick to assemble and replace.

Ideal for temporary rigging applications.

Formed by compressing the wire rope with a metal ferrule.

Ensures a strong, reliable termination.

Commonly used in permanent installations.

Created by cold-forming a metal sleeve around the rope.

Offers high strength and fatigue resistance.

Preferred for critical lifting operations.

As China’s leading rigging supplier, we deliver top-tier wire rope slings with unmatched quality. Here’s why customers trust us:

Cutting-Edge Technology – Our 234-member R&D team holds 360+ patents.

Industry Standards Compliance – We set national & international rigging standards.

Ultra-High Strength – Our slings handle extreme loads with precision.

Corrosion Resistance – Special coatings enhance durability in harsh environments.

We supply wire rope slings for iconic projects like the Hong Kong-Zhuhai-Macao Bridge and Qatar World Cup Stadium. Our products meet CNAS certification and exceed safety expectations.

Whether you need standard or custom wire rope sling eye types, we have the perfect solution. Our team ensures every product meets your exact requirements.

Custom Configurations – Tailored slings for unique applications.

Fast Delivery – Reliable shipping to the USA and worldwide.

Expert Support – Technical guidance for optimal rigging performance.

As a trusted global supplier, we combine innovation, quality, and compliance in every product. Partner with us for rigging solutions that elevate your projects.

Contact us today to order high-performance wire rope slings!

Previous: A Step-by-Step Guide on How to Use Ratchet Straps

Next: ST360 Slant Bed CNC Lathe: Precision Machining Redefined

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used